Starting with a rough shaped stock:

The butt plate is from Brownells and is a copy of a Marlin 1893 butt plate which will work for the 1889, 1893, 1894 and 1895 rifles. The screw holes will be drilled latter.

Make sure the side of the butt plate that goes towards the wood is flat and smooth. File it flat if necessary.

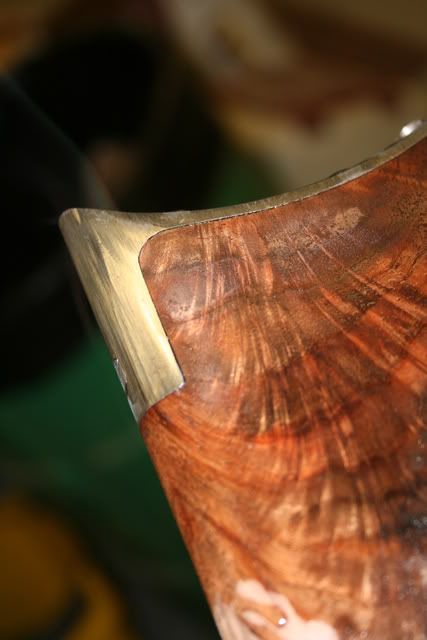

This flat area is key to how well the butt plate will fit. If it slopes front to rear, or side to side, the butt plate will not be positioned properly on the stock. Very carefully file this area flat checking to make sure that when the butt plate rests on this flat area that it is not twisted or skewed on the stock. File this area down only enough that the top of the butt plate is just below the top of the wood. I noticed that the butt plate that I got from Brownells was a little longer than an original Marlin butt plate so that it stuck down farther than the toe of the stock. This excess will be removed later.

Make sure that the butt plate is not tilted, and lines up with the axis of the stock.

For the balance of the fitting, picture the butt plate sliding forward on the flat area at the top of the stock. You will not need to remove any more wood from this area. You will only need to remove wood from the cresent or curved area, and the flat front area. As you remove wood from these two places, the butt plate essentially slides forward.

For the balance of the fitting process, I use Lamp Black which cleans up with water.

Put a coat of lamp black on the inside surfaces of the butt plate. Too thin and it will dry out quickly, too thick and you will get a false reading of the high spots.

Place the butt plate carefully on the stock, sliding it on the flat area until it makes contact. Your first try will probably only indicate a few high spots. Remove the butt plate and carefully file down the high spots. Only take off a little material each time. If you take off too much, you will be chasing your tail. You may have to repeat this process fifty times or more to get a good fit. Be patient. A couple of strokes with the file each time is all that you want to do. Resist the urge to file on the flat area! IMPORTANT: If you tilt the butt plate as you place it on the stock, you will leave lamp black on the toe area of the stock. Even if it doesn't need to be filed down, it will look like it does.

Eventually you will end up with the lamp black showing a fit all the way around.

Next, I have drilled and counter sunk the holes for the screws. I then place the butt plate on the stock and center punch the screw holes. IMPORTANT: Resist the urge to drill these holes until you're completely done with the fitting of the butt plate to the stock. If you don't, and go back and do more fitting, you will have problems.

Drill a slightly undersized hole the full depth of the screw length. Coat the screws with paste wax before screwing them in. The screws should go in fairly easily. If they don't , drill a slightly larger hole. If you really crank on the screw to get it to go in, YOU WILL CRACK YOUR STOCK! Use extra care with the toe screw.

Once the butt plate is screwed to the stock, I use a belt sander sand down the wood and metal together. Use great care with a belt sander. It's advantage is that it removes a lot of material quickly. It's disadvantage is that it removes a lot of material quickly. Go slow and don't gouge the wood.

If you are patient and take your time, you will get a fit that you can be proud of!

-jim