THE BEFORE PHOTOS:

The metal parts were fairly easy to clean up, with few scrtaches or dings. Markings were in excellent shape. The wood was a bit more work. I soaked the wood in vinegar, then steamed them repeatedly using my wifes iron and a towel soaked in vinegar. (It's a good thing my wife doesn't read my posts.) The vinegar eventually removed the burned smell.

I then used Klean Strip two part wood bleach to remove any remaining stains. An oil rubed finish was then applied to the wood.

I recently moved to Cody, WY, and this was my first restoration project after setting up my equipment. Our source of water is from a natural spring, and I was anxious to see how the water worked for CCH'g. The first attempt, using the spring water was a failure. The water is apparently too hard, with too much Calcium. The colors were very muted, with almost no pattern. It looked really blah. I next tried treated soft water. A little beter than the hard water, but still unacceptable. I suspect that there was too many Sodium ions (a result of removing the Calcium). For the third try and final try, I used distilled water. The results proove that the quench water has a profound bearing on the results. If you're having trouble with your CCH'g, the first place to start trouble shooting is the water.

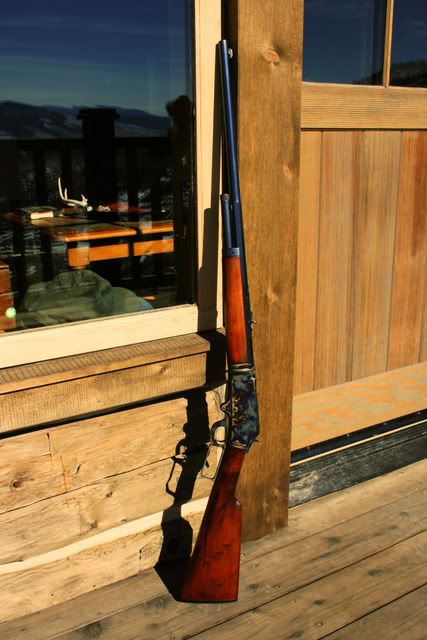

THE AFTER PHOTOS:

CCH'g Data:

1:1 bone to wood charcoal ratio

2.5 hours at 1350F, then cooled to 1100F and allowed to stablize before quenching

Distilled water, aerated for several hours.

Water temp at quench 33F. (It gets cold up here) The aeration kept the quench water from freezing.

Dissolved Oxygen measured prior to quench was 14 PPM.

-jim